Macfab Blog

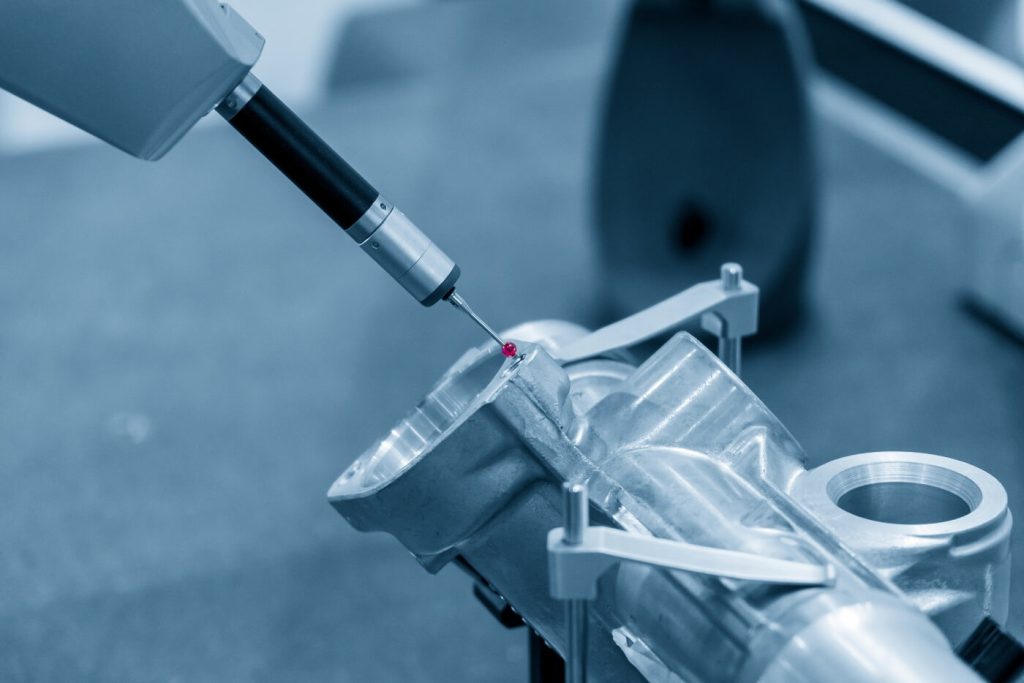

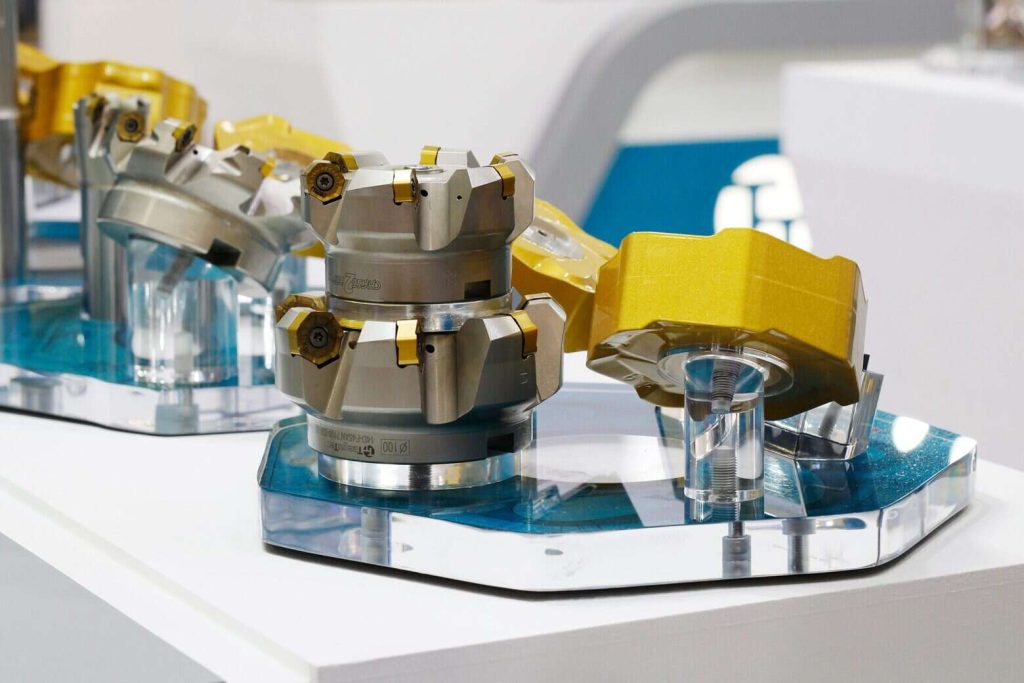

Why Inspection is the Backbone of CNC Machining: How Advanced Tools and Technology Ensure Precision

In precision manufacturing, there’s no room for guesswork. When you’re working in industries like aerospace, defence, medical, or electronics, even the slightest deviation from a specification can have enormous consequences — from wasted material costs to safety risks and product recalls. The quality control process isn’t just a final step in production; it’s a critical […]

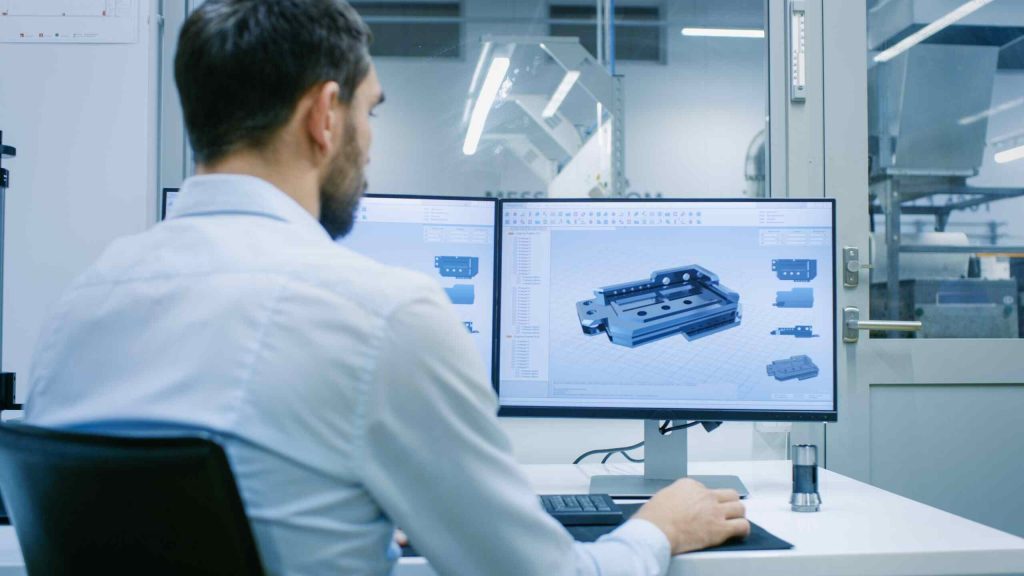

How to Choose the Right Precision Machining Partner: A Guide for Manufacturers and Engineers

Building high-quality, precision-manufactured parts and components requires a partner you can trust; a partner who has the credentials, level of expertise, and experience to provide you with high-quality products or equipment. Choosing the right partner is essential, as that can impact everything in your supply chain. In today’s market, finding the right fit can feel […]

Your Guide to Aerospace CNC Machining: From Prototype to Production

You need a complex part manufactured. You have options, and with those options come plenty of questions. Navigating from concept to finished product can feel overwhelming, but there are clear steps you can take to make the journey smoother. The good news? You don’t have to figure it all out on your own. At Macfab, […]

Strengthening the Critical Minerals Supply Chain: Strategies for Stability and Innovation

Securing the critical minerals supply chain has become imperative for countries globally. As economies evolve and the demand for high-tech and clean energy technologies increases, nations are grappling with the challenge of ensuring an adequate supply of these key commodities. The government of Canada, with its critical mineral resources and strong commitment to responsible mining […]

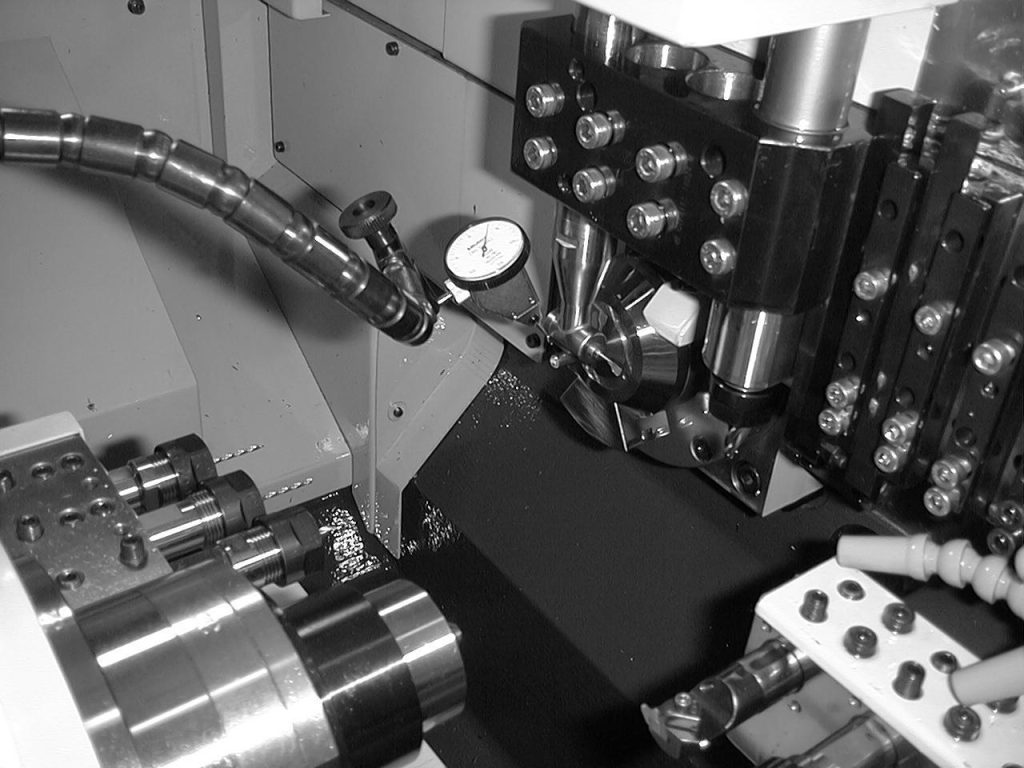

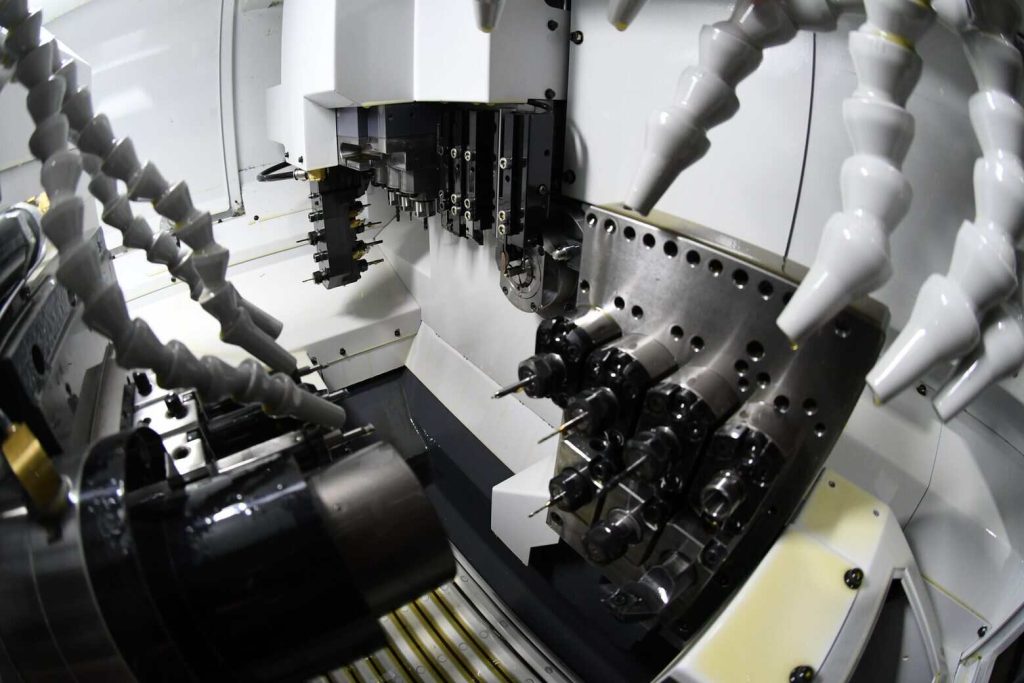

Precision Military Components Made with CNC Swiss Lathes

The defence industry has always pushed the limits of what’s possible—and demanded the same from its manufacturing partners. From advanced optics and secure communications to guided munitions and drone systems, modern militaries operate at the leading edge of science and technology. These innovations depend on an array of ultra-precise mechanical and electronic components that must […]

Unlocking Excellence with Turnkey Manufacturing Solutions

When you’re building complex, high-precision components, the last thing you want is a fragmented production process. That’s where turnkey manufacturing solutions come in—offering a more innovative and streamlined way to bring designs to life from start to finish. What Makes Turnkey CNC Machining So Valuable Today? Turnkey solutions have become essential in modern manufacturing. With […]

Swiss CNC Machining Versus Conventional CNC Machining

CNC machining is a cornerstone of modern manufacturing, enabling the precise, automated production of complex parts across a wide range of industries. By converting digital designs into physical components with high accuracy and repeatability, CNC machining supports industries like aerospace, automotive, medical, and electronics. Within this broad field, there are several types of CNC machining […]

Essential Guide to the Challenges and Processes of Rapid Prototyping

Rapid prototyping is one of the most effective ways to bring your idea to life early in the development process. It gives you something real to hold, test, and refine—long before committing to full-scale production. Using your 3D computer-aided design (CAD) model, we can quickly produce a physical version of your part or assembly, helping […]

Overcoming the Challenges of Engineered Plastics in CNC Machining

CNC machining often brings images of oddly shaped aluminum parts or hardened steel gears taking shape under spinning bits. The machines are large, complex, and powerful. But there’s another side to precision production—one that’s softer but no less technical: machining engineered plastics. We’ve all seen how plastic increasingly replaces metal parts to save on weight […]

Benefits of Onshoring and Localization of CNC Machining in North America

For several years, the overseas manufacturer has been the default for companies looking to cut costs. Whether it’s electronics, toys, or household appliances, many manufacturers make their products thousands of kilometres from where they are sold. Low labour costs and large-scale operations overseas made offshoring the go-to strategy for mass production. However, what if you […]

Reducing Turnaround Time with 5-Axis Machining: A Win for Efficiency

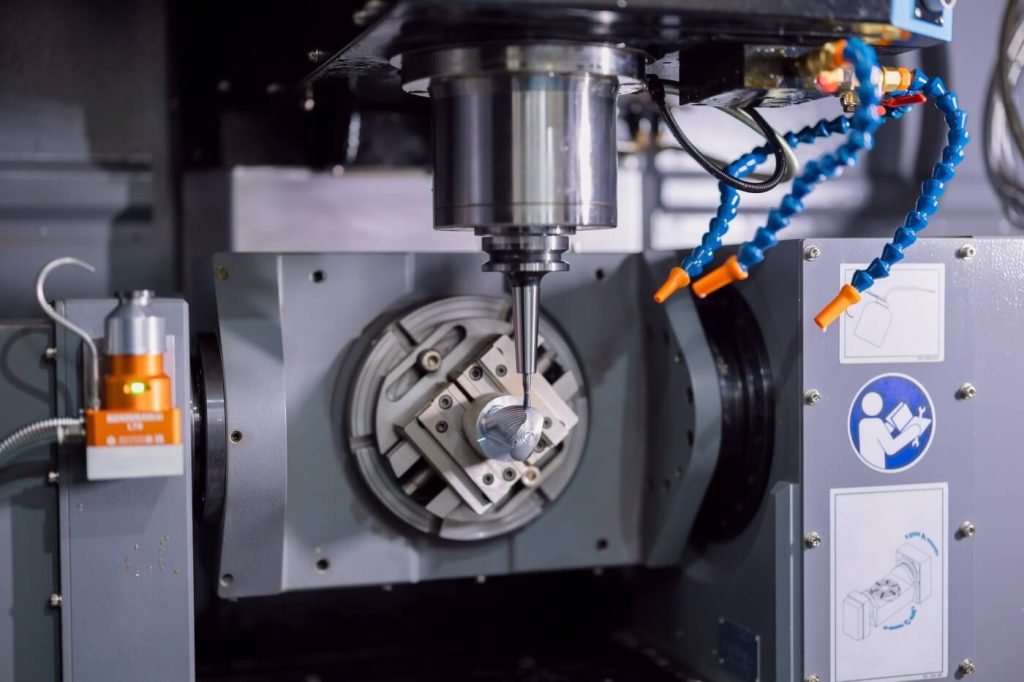

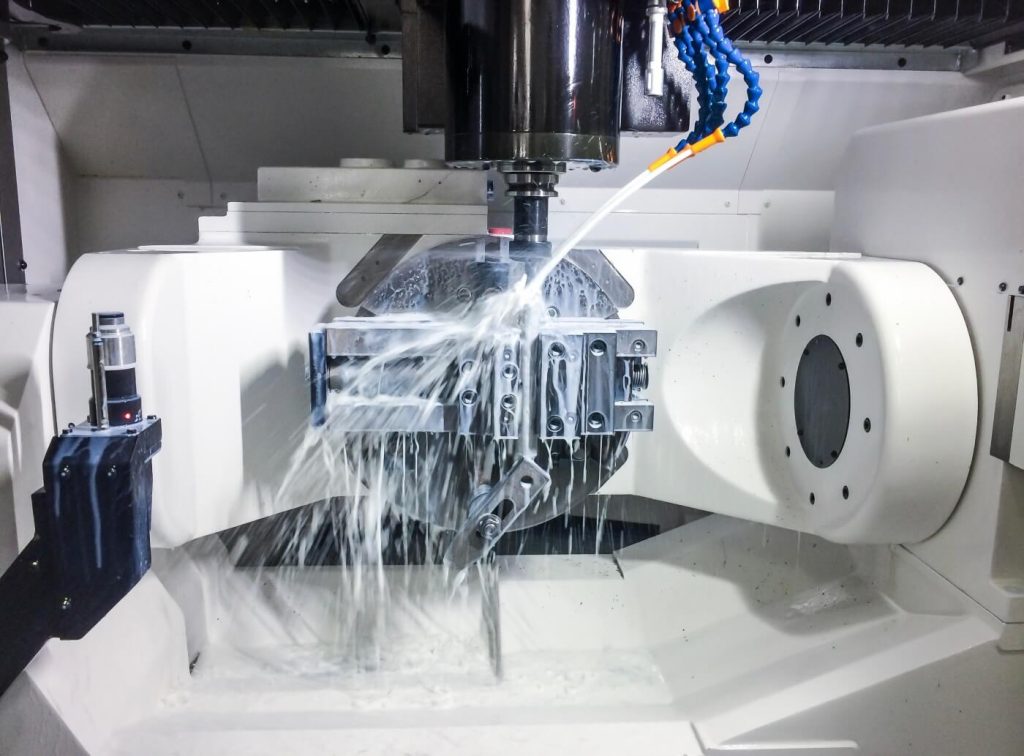

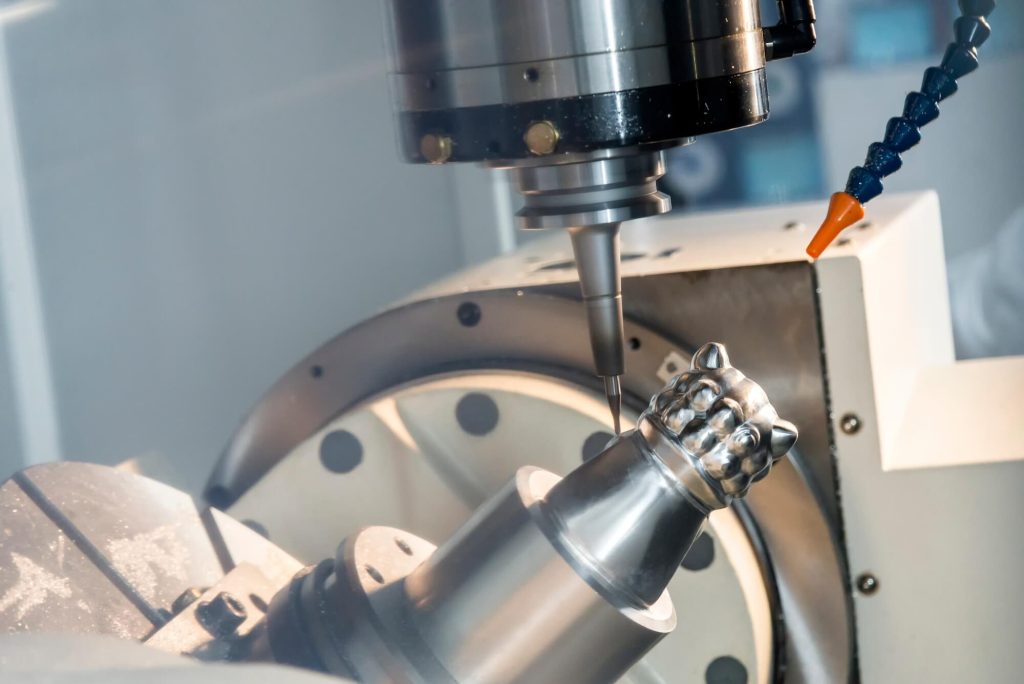

5-axis CNC machining is an advanced manufacturing process where the cutting tool or the workpiece can move simultaneously along five different axes: the three traditional linear axes (X, Y, and Z) and two additional rotational axes (commonly referred to as A and B, or A and C). This multidirectional movement allows the tool to approach […]

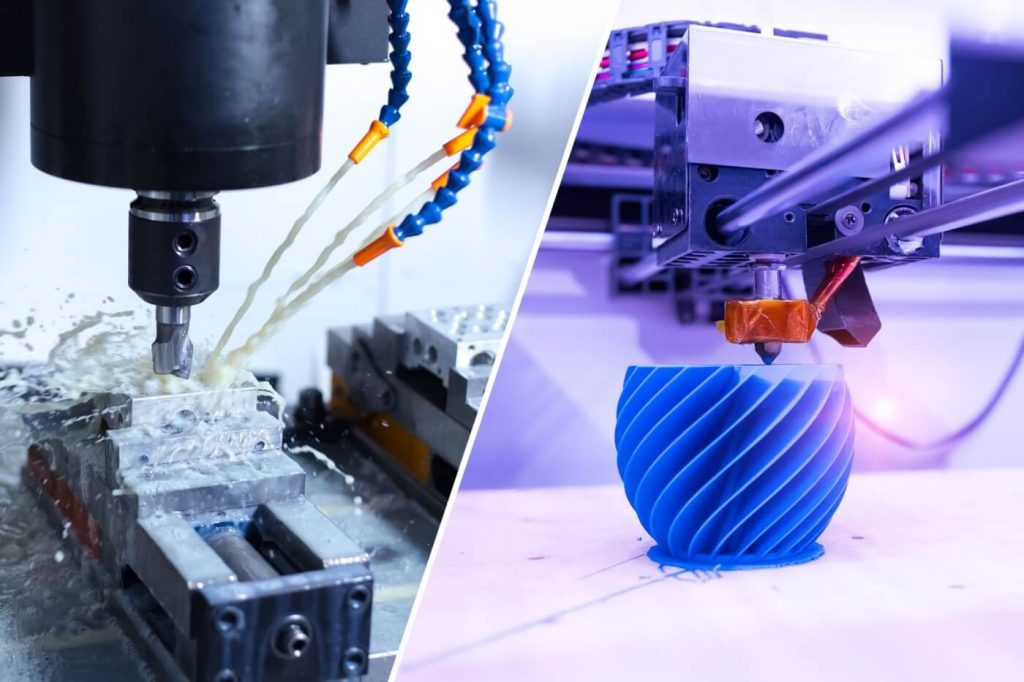

Harnessing Hybrid Production: The Synergy of Additive Manufacturing and CNC Machining

Additive and subtractive manufacturing are the two primary approaches used in today’s modern production environments. Additive manufacturing (AM), or 3D printing, builds components layer by layer and is ideal for creating intricate geometries, internal structures, or multi-material regions. On the other hand, subtractive manufacturing (SM), like CNC machining, removes material from a solid block, achieving […]

The Importance of Inspection and Testing in Aerospace CNC Machining

Critical aerospace components require precision. Any defects in a machined part can lead to catastrophic failures, endangering lives and compromising aircraft safety. Rigorous inspections and tests help identify and eliminate such flaws and maintain a high level of precision during the CNC machining processes. The Significance of Rigorous Aerospace Standards The AS9100 standard is an […]

Meeting the Challenge: CNC Solutions for Aerospace Materials

CNC machining of aerospace materials like titanium and Inconel presents several challenges due to their unique properties. The materials used in aerospace are strong, tough, and hard, making them ideal for the aerospace industry but create challenges for the high-precision machining process. The Nature of Aerospace Materials Titanium is a high-strength material that does not […]

Integrating Design and Assembly: Collaborative Strategies for Complex Components

At Macfab Manufacturing, we have a common goal: We will produce the most precise and complex components using collaborative relationships among product design, engineering, production, and assembly while controlling production costs. Our “One Stop Shop” approach highlights our commitment to form, fit, and function throughout a product’s life cycle. The One-Stop Shop Advantage Our “One […]

Empowering Employees: Macfab’s Approach to Leadership Development

At Macfab, we aim to create a supportive work environment that encourages and empowers employees. These are not merely words taken from a standard mission statement. Instead, they are part of our commitment to cultivating a progressive work environment that develops leaders within the company. Here is our ultimate goal in this endeavour: The Core […]

Collaborative Engineering: How Macfab Partners with Innovators

At Macfab Manufacturing, collaboration is at the heart of everything we do. Specializing in high-precision CNC machining, we work closely with our clients to transform ideas into reality. Our approach goes beyond traditional manufacturing; it’s a partnership built on shared knowledge, open dialogue, and a deep commitment to optimizing designs for manufacturability through collaborative engineering. […]

Optimizing Your Design for CNC Machining: Tips for Engineers

CNC design optimization involves refining part designs to improve manufacturability, reduce production time, and lower costs while maintaining or enhancing product quality. This approach considers various aspects of the CNC machining process during the design phase to create efficient parts that produce and meet functional requirements. These integrated design and engineering approaches result in more […]

How AS & ISO Certifications Impact Your CNC Project Outcomes

Reputable CNC machine shops build their production process on quality and reliability. CNC machining ensures high-quality parts and components that meet the most demanding quality standards. AS and ISO certifications significantly influence CNC project outcomes by providing quality, dependability, and consistency in CNC machining services. These international standards assure clients that a CNC company or […]

Streamlining Inspection Processes with 5-Axis CMM Technology

The precision in CNC machining ensures high-quality products that meet exact specifications and function correctly. It allows shops to produce components with tight tolerances, complex geometries, and intricate designs, essential in aerospace, medical devices, and the automotive industry. A manufacturer’s inspection process helps maintain quality standards, and the 5-axis coordinate measuring machine (CMM) is an […]

The Vital Role of Material Selection in CNC Prototyping

Material selection in CNC prototyping is critical. CNC prototyping refers to using CNC machine tools to produce physical models directly from digital designs. The process transforms 3D designs into prototypes, allowing product developers to test and refine their concepts before mass production. The importance of CNC prototyping in product development includes: High Precision and Accuracy: […]

CNC Machining & Medical Analytics Equipment Manufacturing

CNC machining plays a critical role in producing accurate and high-quality medical devices. This article highlights its importance in medical analytics equipment manufacturing, such as blood and urine analysis devices and cancer research tools. Learn how CNC machining improves precision and drives innovation in medical technology. The Marriage of Medicine and Machining Analytical devices, including […]

The Precision of 5-Axis CNC Machining in Advanced Geometries

5-axis machining is an advanced form of CNC (Computer Numerical Control) machining that allows manufacturers to create intricate and complex parts by moving a tool or workpiece in five different axes simultaneously. This approach differs from traditional 3-axis machining, which operates along three linear axes (X, Y, and Z). In 5-axis machining, two additional rotary […]

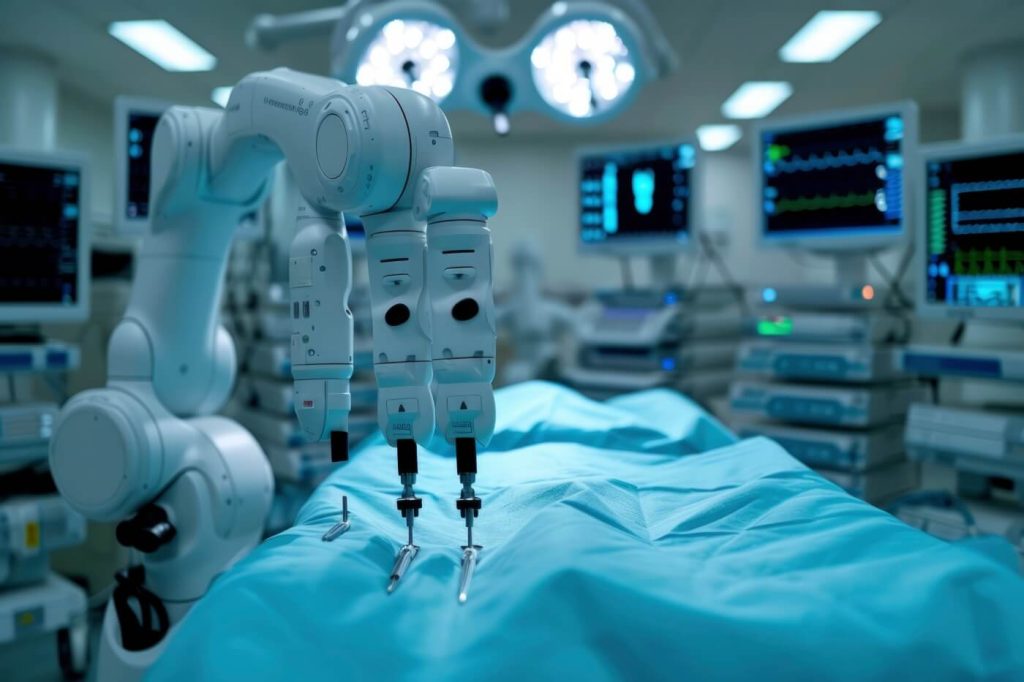

Complex Assembly Demands in Aerospace and Medical Industries

Due to rapid technological advancements and stringent regulatory requirements, the aerospace and medical industries are experiencing increasingly complex assembly requirements. In the aerospace sector, precision engineering and the integration of cutting-edge technologies like advanced materials, avionics, and automation are essential to ensure safety, efficiency, and compliance with international standards. Similarly, the medical industry faces heightened […]

The Role of CNC Machining in Creating Cleanroom-Ready Medical Equipment

Cleanroom-ready medical equipment plays a crucial role in preventing contamination and ensuring patient safety in the healthcare sector. CNC machining simplifies the cleaning process for medical device parts due to its ability to produce precise components with high-quality finishes and material versatility. The exact specifications and smooth surfaces created through CNC machining help meet the […]

Developing Soft Skills: Communication and Leadership for CNC Machinists

The computer numerical control (CNC) machining industry significantly emphasizes technical skills, such as precision programming, machine operation, and maintenance, due to the specialized nature of the work. Although technical knowledge is essential for job performance and operational efficiency, soft skills for CNC machinists – such as effective communication, adept problem-solving, attention to detail, and strong […]

The True Cost of Poor Quality in CNC Machining

Poor quality in CNC machining processes can lead to quality issues, increased waste, higher costs, and customer dissatisfaction. This article highlights the vital role of precision and quality assurance in providing product reliability, efficiency, and compliance with industry standards, ultimately safeguarding a company’s reputation and profitability. Understanding the Implications of Poor Quality ‘Poor quality’ in […]

Securing the CNC Workflow: Proven Strategies to Protect Your Intellectual Property

CNC intellectual property (IP) protection is critical since it safeguards innovative designs and proprietary information from unauthorized use or theft. Decision makers and design engineers are concerned about the security of their valuable IPs, which can lead to competitive disadvantages if compromised. This article offers insightful strategies for protecting IP in CNC machining, ensuring that […]

Deciphering Medical-Grade Materials for CNC Machining

High precision and accuracy are critical for manufacturing components in the medical industry, as even the slightest error can have significant repercussions. This requirement is especially true for analytical devices and medical equipment requiring meticulous engineering to meet stringent standards. Macfab stands at the forefront of this demanding field, expertly crafting components for medical diagnostics, […]

Meeting the Demand for Critical Components in CNC Machining

Precision and consistency are essential when manufacturing critical components. These parts are defined by their important role in a more extensive system or a product’s functionality, safety, and reliability, and they are integral to the operation of complex systems. Any failure or defect in these highly-precise parts can lead to significant malfunctions, safety hazards, or […]

Overcoming Barriers to IoT Integration in CNC Machining

CNC machining is a manufacturing process in which computer software dictates the movement of cutting tools and machinery. This technology is vital in modern manufacturing because it can produce highly precise and complex parts with minimal human intervention, enhancing both efficiency and consistency. Integrating Internet of Things (IoT) devices with CNC machining opens up more […]

Navigating Material Shortages: Proactive Strategies for Procurement

In today’s unpredictable global supply chain, the manufacturing industry struggles with navigating material shortages, an issue worsened by emerging supply chain disruptions. These challenges threaten seamless raw material acquisition, risking production schedules, and driving up costs. Consequently, it is more crucial than ever for manufacturers to develop and implement robust strategies that ensure a steady […]

One-stop Machine Shop for Your CNC Machining Solutions

There’s real business value in keeping things simple. Complicated arrangements in manufacturing introduce possible points of failure, delay, and hidden costs. That’s perhaps the most compelling argument for working with a quality one-stop CNC machining solutions shop like Macfab. If a problem arises, you know exactly whom to call. If your production needs change, a […]

Bridging the Skills Gap: Fostering a Future-Ready Workforce in CNC Machining

The skills gap in the CNC machining industry refers to the discrepancy between the skills employers need and the skills that potential employees possess. As technology advances, CNC machinery becomes more complex, with increasing automation and new materials and techniques. However, the workforce may only sometimes keep pace with these advancements, leading to a gap […]

CNC Machining for the Energy Sector: Powering Innovation with Aluminum

Cutting-edge technology in the energy sector plays a crucial role in developing sustainable practices and efficient power solutions, especially as the demand for clean energy grows amid global concerns about climate change and resource depletion. Renewable energy components for technologies, such as solar panels, wind turbines, and hydroelectric generators, rely heavily on precision engineering and […]

Factors Affecting the Cost of CNC Machined Parts

When you’ve got a new part to manufacture, it doesn’t take long for the price tag to come up. CNC machining costs can be daunting. Fortunately, the cost of CNC machined parts is not cast in stone. You do have some ability to keep your costs down. It all hinges on attention to detail and […]

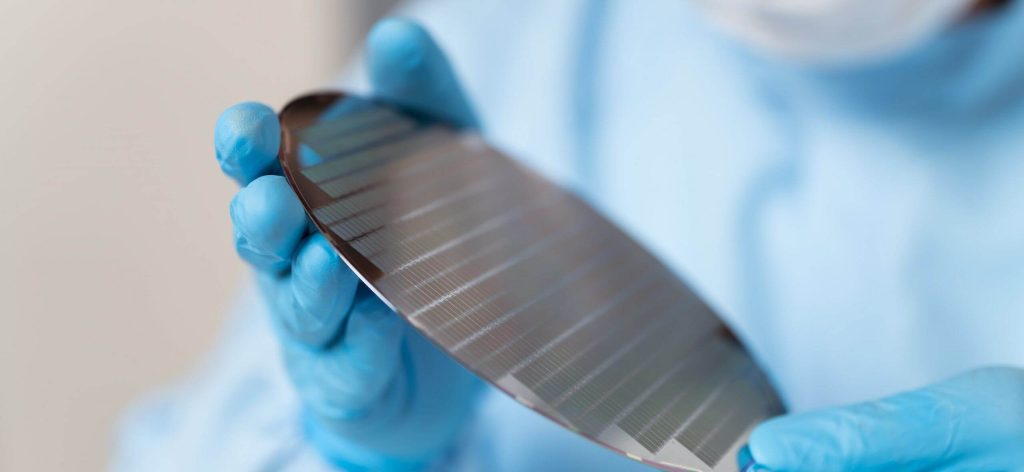

Micro Machining For Customized Medical Devices

The individual components in computer chips shrink in size year after year. You could fit 200,000 modern transistors in the length of the first transistor from 1947. Mechanical parts continue to shrink right along with their electronic counterparts. Gears, switches, pumps, and countless other devices are routinely produced today on scales almost too small to […]

CNC Machining for Minimally Invasive Surgery

Manufacturing medical devices, especially those used in minimally invasive surgery (MIS), requires precision, reliability, and quality. In MIS, small incisions allow the insertion of a tiny surgical tool and camera into the patient’s body. This technique dramatically reduces trauma and recovery time compared to traditional surgery. However, because of the smaller incisions and the delicate […]

The Journey of a CNC-Machined Medical Device

Precision and reliability are essential in the medical device manufacturing industry due to these devices’ critical role in patient care. A CNC machining process allows for creating small parts with extremely high precision and accuracy, meeting the tight tolerances for surgical instruments and analytical medical components. Although a CNC shop is a must for the […]

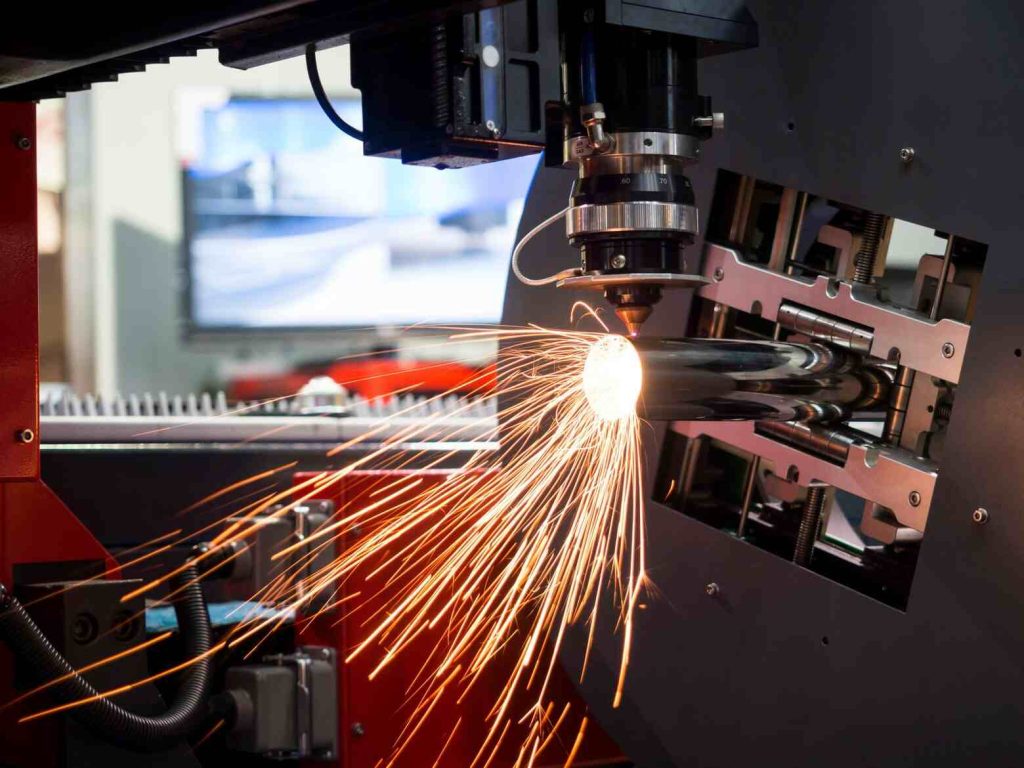

Best CNC Machining Service For Metal Fabrication

Generally speaking, the decision of what CNC machining services best suit your project is not a decision you have to make. Technically that is determined by the project itself. The physical dimensions, tolerances, kerf widths, features, and details tend to dictate what CNC machining services are required to produce it. Of course, nothing’s that cut […]

Minimizing Production Downtime in CNC Operations

In the productive world of CNC machining, downtime is more than a minor inconvenience; it is a significant disruption that leads to lost productivity, quality issues, and reduced profitability. Understanding the causes of downtime and implementing proactive maintenance practices are vital to mitigating these risks. Effective maintenance ensures the longevity and reliability of CNC machinery […]

Long-term Strategic Partnerships in CNC Manufacturing

There has been a conspicuous shift in market dynamics as companies choose to ‘reshore’ their production processes. This trend involves bringing back manufacturing operations to their home countries or regions instead of outsourcing them to distant locations. One aspect of reshoring is the increased emphasis on local, reliable CNC manufacturing partnerships. By partnering with local […]

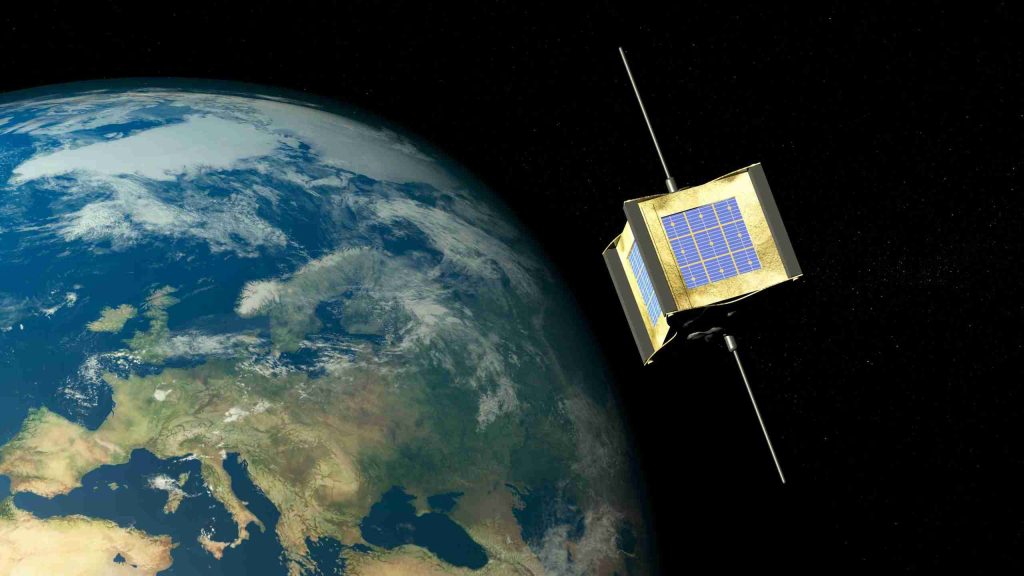

Propelling Futures: Macfab and Launch Canada

When we think about space exploration, we often imagine astronauts venturing into the unknown and advanced rockets cutting through the atmosphere. However, critical to these achievements is the precision engineering that occurs behind the scenes. Macfab has long been one of the unsung heroes in this domain, leveraging advanced machinery to fabricate high-precision parts for […]

Breaking Down the Cost Drivers in CNC Manufacturing

Computer numerical control machines are permanent fixtures in today’s machine shop. The CNC machining process has emerged as a cornerstone in modern manufacturing, providing unparalleled precision, efficiency, high speeds, and repeatability in production. As industries strive for innovation and customization, the demand for the precision generated by CNC milling and turning continues to grow, making […]

The Role of Workplace Design in CNC Manufacturing

In the contemporary industrial landscape, efficient workplace design in manufacturing is no longer a luxury but a necessity. A well-organized, safe, and innovative workspace has a significant positive impact on employee health, productivity, morale, and, ultimately, the bottom line. This article focuses on the principles and benefits of effective workplace design in manufacturing companies, shedding […]

Why CNC Careers Are Future-Proof

CNC machining is a cornerstone of manufacturing processes and refers to the automated control of machining processes using a computer and special software. The significance of CNC machining lies in its precision, efficiency, and scalability, which are vital for competitiveness in the manufacturing sector. Beyond its immediate utility, the future-proof nature of CNC careers is […]

Understanding CNC Programming Basics: A Beginner’s Guide

Picture a symphony under the guidance of an orchestra conductor. The conductor interprets the musical score, dictating tempo and rhythm and ensuring seamless coordination among musicians to produce a flawless performance. But wait! That’s not all. In the background, there’s more than you realize. You have light and sound technicians, stage organizers, etc. All work […]

The Essential Guide to CNC Machine Maintenance

It’s nearly impossible to overstate the significance of CNC machine maintenance in the manufacturing industry. These pieces of equipment are the lifeblood of any manufacturing operation, and a strict maintenance schedule directly impacts productivity, efficiency, safety, quality, and environmental concerns. Consider Macfab Manufacturing, a company that operates over 50 CNC machines, and our commitment to […]

Understanding the Complexities of Exporting Controlled Goods

Exporting controlled goods presents challenges businesses must navigate to meet specific requirements. Complex export regulations, export permits, and inconsistent international laws can make the process demanding. Particularly for manufacturing companies, the task becomes even more critical given their products’ precise nature and potential dual-use. These companies often find themselves at the crossroads of technological innovation […]

Embracing Sustainable Energy Innovations

Sustainable energy innovations, including solar energy, wind farms, hydro, and other renewable energy sources, have become essential for our planet’s future. They significantly combat climate change by drastically reducing greenhouse gas emissions compared to conventional fossil fuels. Implementing these clean energy alternatives is rapidly increasing worldwide, indicating a positive shift towards sustainability. However, despite this […]

Innovations in CNC Machining: 5-Axis vs. 3-Axis Machining

Computer Numerical Control (CNC) machining stands as a critical cog in the wheel of modern manufacturing processes. Numerous industries use CNC machining operations to produce high-quality parts with complex geometries. Multi-axis machining techniques have revolutionized manufacturing by automating the control of machine tools through precisely programmed sequences. A notable trend in the industry is the […]

Solving Industry Challenges with CNC Prototyping

CNC prototyping has transformed the manufacturing industry using a computer-aided design (CAD) model to quickly and accurately transform a virtual design into a physical product. This automated process significantly enhances precision, efficiency, and repeatability, paving the way for the cost-effective production of a complex final product. Here is what you should know: Importance of CNC […]

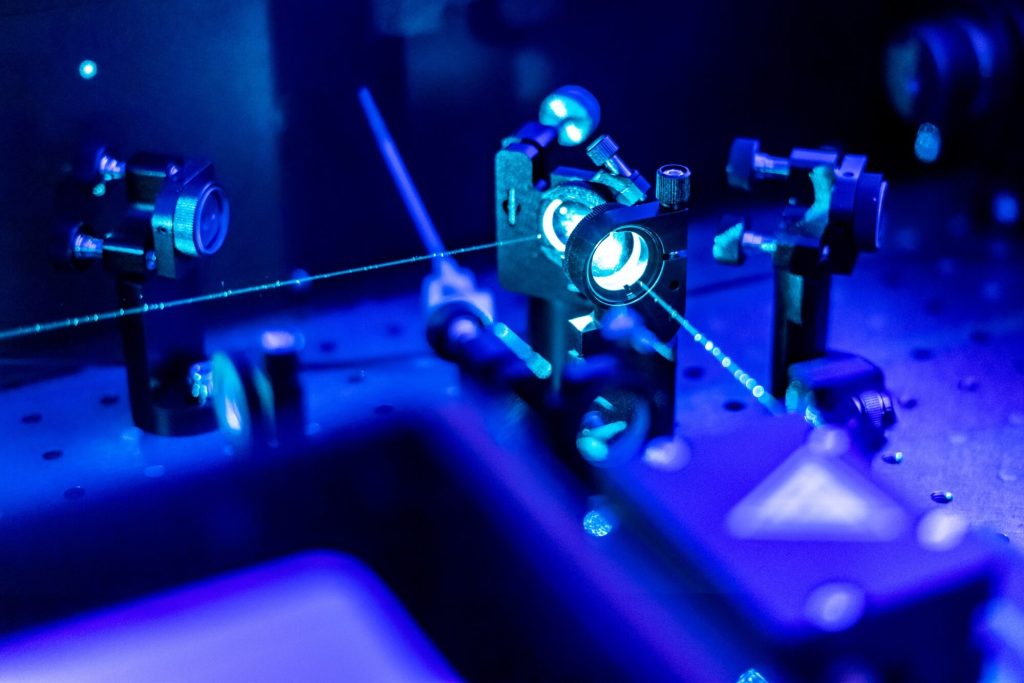

Unleashing Excellence through Macfab’s Production Solutions for Optics

Optics companies operate in a highly technical and precision-driven industry with complex production needs. They require world-class optics manufacturing solutions that include high-precision manufacturing and strict quality control to meet their exacting standards. Macfab Manufacturing provides these production solutions for optical components that require skilled labor, advanced machinery, special cleanliness, and innovative R&D capabilities. The […]

Macfab Manufacturing Ensures OTD and High-Quality CNC Machined Components

The production of high-quality CNC machined components delivered on time is critical to the success of any manufacturing operation. With the increasing complexities of modern supply chains, globalization, and geopolitical tensions, the need for dependable CNC machining services is more important than ever. Macfab Manufacturing, a leading CNC machine shop, is a trusted partner for […]

China Imposes Exports Controls on Critical Mineral

China, the dominant player in the global market for critical minerals, recently announced export controls on minerals that are vital to the production of high-tech products, including computer chips, electric vehicles, and more. The Ministry of Commerce in China has imposed export restrictions on key minerals, including rare earth, gallium, and germanium, citing national security […]

Risks and Opportunities for the Manufacturing Sector as Deglobalization Looms

We stand at a historical crossroads. After enjoying decades of interconnected trade partnerships and economic growth, the tide of globalization is receding. Trade relationships are increasingly fragmented, with the spectre of a significant power standoff between the U.S. and China looming large on the horizon. The need to comprehend the economic implications of this evolving […]

The Importance of Leak Testing and Off-Gas Monitoring in CNC Machining

CNC machining is an essential process in the manufacturing sector, boasting precision, consistency, and flexibility. At Macfab, we’ve taken these core principles to heart, rigorously applying them in every project we undertake. However, amidst the quest for perfect design replication, one element that cannot be overlooked is quality control. We understand this well, therefore, carry […]

CNC Machining: The Unsung Hero in Medical Research

It is quite remarkable how various industries often intertwine and synergize, producing outcomes that push the boundaries of human potential. Take, for instance, the blending of computer numerical control (CNC) machining and medical research – two fields that, on the surface, might appear as distinct as night and day. Yet, when they come together, the […]

Leveraging a Full-Service Quality Control Lab for Precision Control in CNC Machining

Every new product starts at a very human level; then the engineers get involved in making the idea reality by replacing the humans with numbers… lots of numbers. Those numbers provide us with a couple of benefits. They accurately describe how we humans want the device to function -how it should feel, sound, perform, and […]

Enhancing Safety and Security in CNC Machining: Trace Detection of Narcotics and Explosives

If you haven’t run across discussions of trace detectors for narcotics and explosives, you will soon. As we look back on the last decade, it’s truly remarkable to witness our growth trajectory in the field of trace detection for security and defence. We’ve seen our sales in this sector more than triple, reflecting an average […]

Quick Response Manufacturing In The Machining Industry

Hurricanes, pandemics, political upheaval -in a world as interconnected as ours, major events -even isolated to a relatively small area- can throw production for a loop. We now understand better how fragile supply chains really are. CNC machining on demand, like any other complex manufacturing process, has to rely on quick-response manufacturing principles. The Supply […]

The Expanding Role for CNC Machining in Hybrid Manufacturing

It’s a time of tremendous change in manufacturing. Composite materials like carbon nano-fibers and new polymer resins are replacing metals in some circumstances. Additive manufacturing (or 3D printing) is gaining new capabilities every day, with new materials becoming available and new applications coming to market. Meanwhile, CNC machining continues to expand with new axes of […]

Choosing The Right CNC Machining Process for On-demand Production

It was, perhaps, inevitable that the success of Just-In-Time production would find its way to the CNC machining process. Suppliers and wholesalers have for decades now shown the incredible benefits of JIT inventory control. There was an inexplicable disconnect between being able to restock consumer electronics in a day and having to wait months for […]

Macfab’s Contribution to Medical Innovation.

There’s a real Renaissance happening in medicine today, and Advanced CNC Machining is playing a part. When COVID-19 hit in 2020, the first vaccine was rolled out in a matter of months thanks to years of research into mRNA. Prior to that point, the fastest vaccine development had been four years. Putting Advanced CNC Machining […]

The Significance of Quality Improvement Tools in CNC Machining

Manufacturers talk a lot about quality. Everyone wants to be known for putting out quality products. “Quality is our job.” “No one beats our quality!” Well, “Quality” is a great buzzword, but how can you tell what they mean -if they mean anything? In the realm of CNC machining, there are a couple of common […]

Developing Environmentally Sustainable CNC Machining Solution

Environmental sustainability isn’t the first thing that springs to mind when someone mentions CNC machining, but Macfab has made environmental responsibility a key component in our business philosophy. As we see it, doing what we can to promote sustainable manufacturing makes sense for us and our customers. Our operations are tightly integrated. We use the […]

What Future Does Artificial Intelligence Hold for CNC Machining

You can’t escape stories about artificial intelligence these days. The Internet is blowing up with tech’s drive to roll it out and tales -from humorous to frightening- about early results. But rest assured; artificial intelligence is coming. AI is not new in itself. Early systems have been in use for years. These are not the […]

2022 Top Canadian Defense Technology Company

Macfab is both pleased and humbled by the opportunities we’ve been given over the last 35 years. There’s no mistaking that it’s been difficult work. There have been challenges, and we’ve faced each one head-on. At year’s end, it’s traditional to look back with gratitude and forward with expectation. This year, though, we have a […]

Integrated Quality Inspection and Reporting System for CNC Machining

The old adage is “measure twice; cut once”. It’s as true today as it ever was, only in the world of quality CNC inspection, we measure a lot more than twice. The complex shapes, delicate features, and tight tolerances of precision CNC machined parts demand higher accuracy than ever before. It’s those once-impossible designs that […]

Optimization of CNC Machining Process and Time Through Lean Manufacturing

When you organize your CNC machine shop to reduce waste, downtime, and inefficiencies, that’s called lean manufacturing. The underlying principles of lean manufacturing were formed almost a century ago at Toyota Motor Works. In the years since, countless books and papers have been written on the topic and it has become the dominant system in […]

LESSONS LEARNED: CNC Machined parts Cleaning Procedure for Magnesium Manifolds

For decades, manufacturing process R&D has been an integral part of shaping MacFab’s service capabilities and technological advancements. Our lessons learned include “what not to do” as well as “what to do”. Although many of our research projects were, at the time, product specific, the knowledge and experience gained were transferable to a variety of […]

How we ensure quality control of the CNC machining process at Macfab

We get it. Quality control isn’t the most exciting topic. You get paid for production, not QC. But we’ve never looked at quality control that way at MacFab. More than anything else, quality control is what brings our customers back. It’s also how we gauge our own professionalism. We derive a sense of pride from […]

Achieving the Best Surface Finishing for CNC Machined Part

It goes without saying that you want a good finish on your CNC machined parts. If they’re painted or powder coated, you want a nice, shiny defect-free finish. If they’re passivated, plated, anodized, or even bare metal you want to see parts that look like care was taken and attention was paid to making them. […]

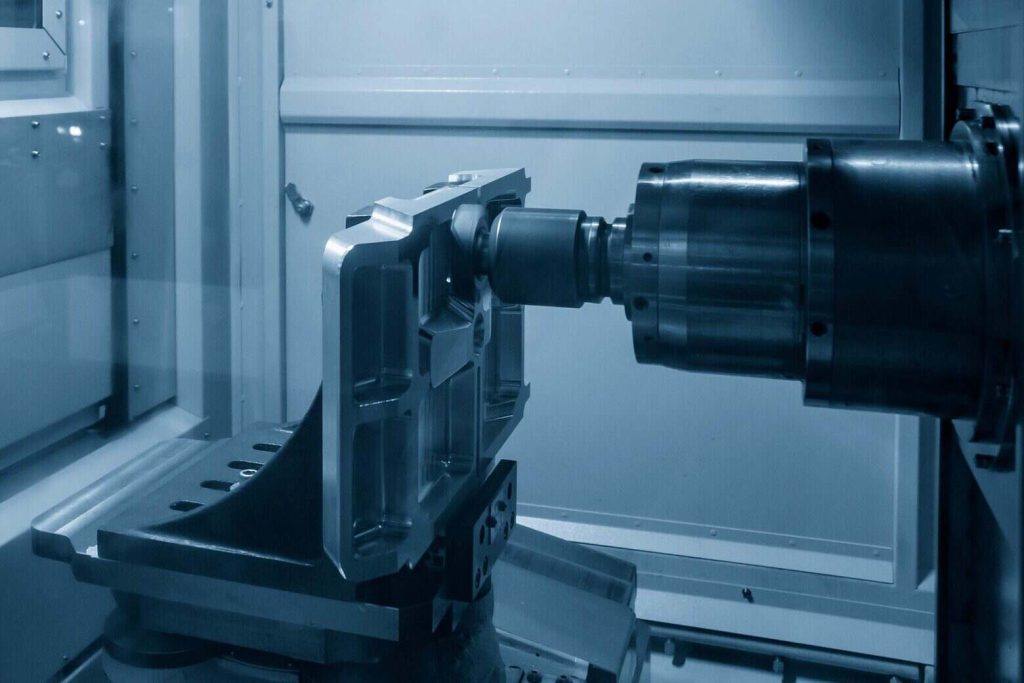

Benefits and efficiency of horizontal CNC machining

You may think it doesn’t matter to you what kinds of machines your CNC machine shop has, but it should. There are distinct differences between horizontal CNC machining and vertical CNC machining and those differences can save you money. Keeping a Clean Work Area Horizontal CNC machining has some serious advantages over its vertical cousin. […]

Our Latest Multi-Million Dollar Investment in CNC Machines

You don’t stay on top of your game by sitting still. For CNC machine shops, that means keeping up with the latest technology and maintaining the latest abilities for your clients. Macfab has just completed a multi-million dollar round of investments in CNC machines to make sure we can continue to provide the most advanced […]

5 Tips to Design Machine Parts for CNC Machining

You’re designing a new part for CNC machining. Design parts for CNC machining with cost savings in mind from the beginning. There are a few details you can address that can cut the cost of your CNC machined parts and speed up production. Know Your Materials Find out the standard size your raw materials come […]

When Precision CNC Machining Is A Race Against Time

When a new disease emerges, there’s a race to find the cause -bacterial, viral, fungal, environmental -some combination of those? The cause informs us on how to fight the disease. You wouldn’t think of a precision CNC machining shop like Macfab being involved in a race for a cure for a deadly disease, but that’s […]

CNC Machining for the Largest Electric Vehicle Manufacturer in the World

The journey of a thousand miles begins with a single step. It’s an old Chinese proverb, and it describes the fortunes of one of Macfab’s clients perfectly. The First Step – to the Garage Years ago, a young Canadian engineer started a company in his garage. He developed a machine which could do a simple […]

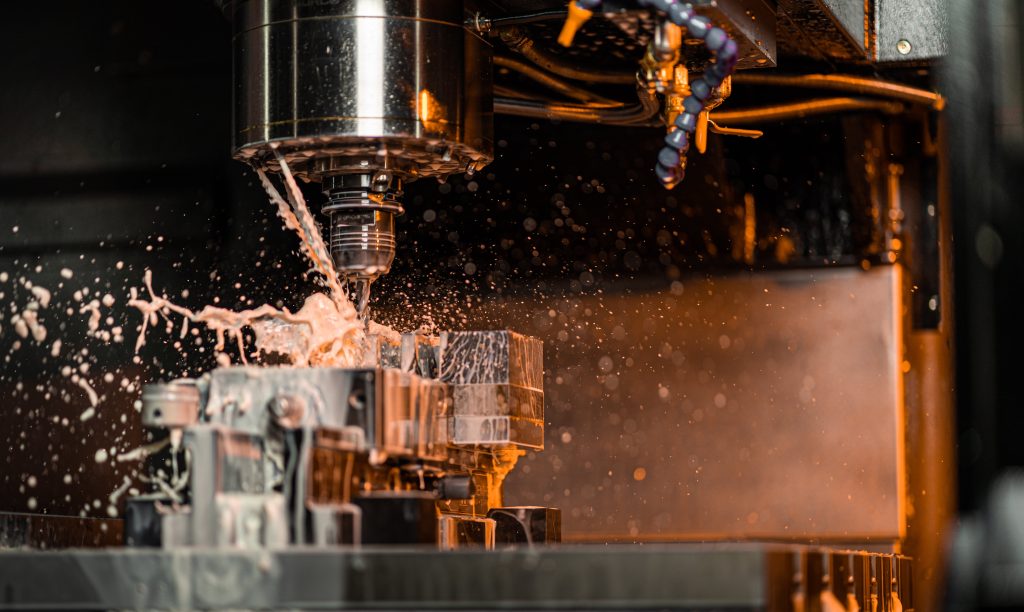

CNC Milling – Process, Machines & Operations

It seems like if you want to get a part manufactured today, you’re going to run into 3D printing and CNC. It’s as if the entire world of manufacturing has gone to those two technologies. Really, though, that’s not the case. 3D printing is a different beast; it’s almost always plastic-based; it’s slow, and generally […]

Saving Lives Through the COVID-19 Ventilator Program

Everyone remembers the early weeks of 2020; nobody wants to go back there. As COVID began to -quite literally- suck all the oxygen out of the room, demand for mechanical ventilators exploded. This was just as countries began to go into lockdown and supply chains became unreliable around the world. In response, Ottawa announced $1.1 […]

Welcome to the Future of Space

We see our possible futures through the eyes of science fiction writers. Jules Verne’s 20,000 Leagues Under the Sea stretched the limits of imagination. Now it passes without notice on nuclear subs. Anyone with the money can fly around the world in two or three days, never mind the 80-day challenge that astounded Victorian readers. […]

CNC Machining vs 3D Printing: The Best Option For Medical Machine Parts

Medical CNC machining has been the de facto standard for producing medical devices and machine parts for decades. In recent years, though, 3D printing has entered the field. Sometimes it can be confusing trying to figure out which technology is better suited to a particular situation. Nothing in Common It would help if the two […]

CNC Turning or CNC Milling: The Difference And When To Use

In most cases, the choice between using CNC turning or CNC milling to produce a part is obvious. There are times, however, when the decision is less cut and dried. CNC milling holds the raw material still while tools move around it, removing what doesn’t belong in the final part. CNC milling is the obvious […]

CNC Machining Challenges for the Medical Industry

No field presents more challenges to manufacturers than the medical industry. The extreme tolerances are always there, but the rapid rate of change constantly creates new demands, and once in a while, curveballs can come hard and fast. The Leading Edge MacFab’s Swiss turning machines, precision milling and lathe work keep us on the leading […]

Importance of Clean Room Services for the Medical Industries

Clean rooms in are nothing new, but their use in assembly is growing dramatically now. This is especially true in CNC machining for the Medical industry. More than ever, medicine today relies on devices -both implanted and external- which are amazingly sensitive and complex. Clean room assembly is required for many of these. Even more […]

Benefits of Swiss Turn Machining

More than ever before, today’s technology is concerned with precision. Part tolerances and fittings are now routinely measured on the nanometer scale. It’s no surprise that incredibly precise machining is becoming more vital every day. That’s where Swiss turn machines come in. When complex parts have to meet exacting standards, there’s simply no better technology available. Originally designed for […]

The Macfab Experience – Solving Manufacturing Challenges

As a senior level purchasing manager the selection of the right precision CNC machine shop for your requirements can mean the difference between a high stress job and a high stress job with long sleepless nights. Across industries such as medical, security and defense, supply chains became brittle during the pandemic. Many purchasing managers witnessed […]

Ben Machine Products Aquires Macfab Manufacturing

We are proud to announce Macfab Manufacturing Inc. has joined the Ben Machine Products family. Backed by over 35 years of experience, Macfab Manufacturing Inc. will continue to offer precision manufacturing expertise to its broad range of customers in the life sciences, defence, aerospace, environmental and power generation industries. Ben Machine Products is the ideal […]