Reducing Turnaround Time with 5-Axis Machining: A Win for Efficiency

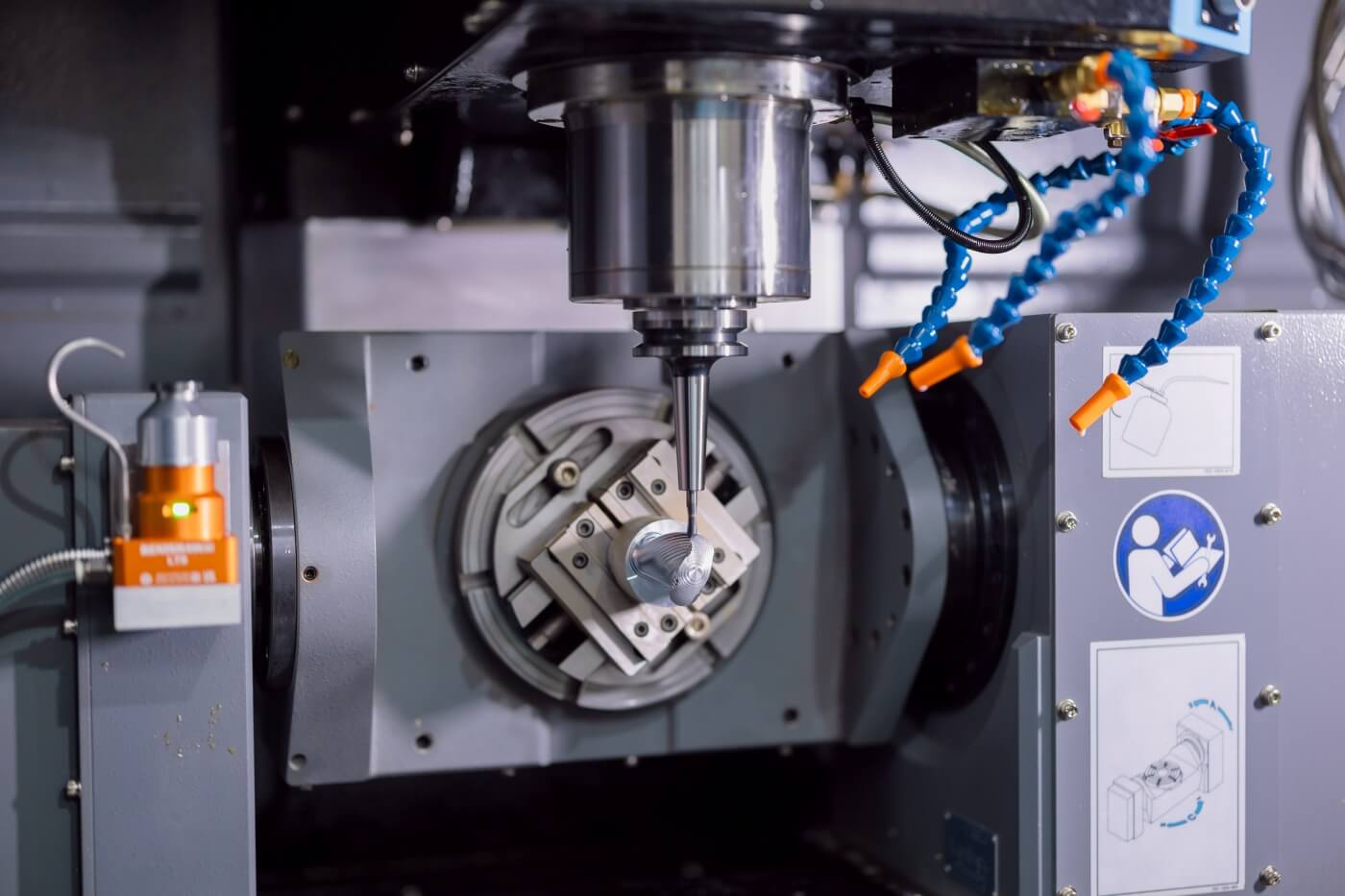

5-axis CNC machining is an advanced manufacturing process where the cutting tool or the workpiece can move simultaneously along five different axes: the three traditional linear axes (X, Y, and Z) and two additional rotational axes (commonly referred to as A and B, or A and C). This multidirectional movement allows the tool to approach the part from virtually any angle, creating highly complex parts and precise components in a single setup.

The Efficiency Gains from 5-Axis Machining

5-axis machining enables access to all five sides of a hexahedron block in a single setup, saving time and reducing the need for additional manual intervention. It allows machining parts of intricate shapes, undercuts, and features that are impossible or impractical with 3-axis machines.

Fewer setups mean a lower chance of cumulative error, and the ability to use shorter, more rigid cutting tools improves tolerances and provides a quality surface finish.

Simultaneous multi-axis movement and single-setup machining significantly reduce cycle times, increase throughput, and eliminate the need for custom jigs and fixtures, resulting in time and cost savings.

Less manual labour, reduced fixturing, and faster production lead to lower manufacturing costs, while shorter tools minimize vibration and wear, extending tool life and maintaining quality.

Reducing Turnaround Time with Single-Setup Operations

Shorter turnaround times ensure the optimal use of resources, equipment, and personnel, minimizing idle time and maximizing output. This translates to higher production volumes, reduced costs, and increased revenue potential. Every minute saved in production means potential profit, especially in industries where downtime equals significant financial loss.

Since 5-axis machines can access multiple faces and complex angles of a part in a single setup, they eliminate the need for numerous repositionings and dramatically reduce setup time. This streamlining minimizes interruptions and speeds up production, saving time, labour, and operational costs.

Optimizing Production with High-Speed Precision

Enhanced tool orientation and optimized cutting paths allow for faster material removal and reduced idle time, further accelerating production. The optimized tool paths and cutting conditions help extend tool life and reduce replacement costs. These benefits have the cumulative effect of shortening cycle times and speeding up part delivery.

Meeting and Surpassing Client Expectations

Meeting or exceeding customer expectations for delivery times helps retain customers and win new business, as faster turnaround times can be a key differentiator in competitive markets. Companies that can offer expedited production without compromising quality gain a competitive advantage over those that cannot.

The Future of Manufacturing Efficiency

5-axis CNC machining enhances modern manufacturing by enabling the production of complex and precise parts in a single setup, which significantly reduces machine time and manual intervention. These machine tools boost efficiency, minimize errors, and lower costs, which are essential for companies aiming to streamline operations while maintaining high-quality standards in competitive markets.

This machining technology revolutionizes the manufacturing of complex, high-precision parts by allowing simultaneous movement along five axes. Its main advantages include reduced setups, the ability to machine complex geometries, improved accuracy, better surface finishes, faster production times, and lower costs. These benefits make it the preferred choice for industries requiring intricate, high-quality components.

Partner with Macfab for Smarter, Faster Manufacturing

If you’re looking to gain a competitive edge through faster turnaround times, superior precision, and lower production costs, now is the time to rethink your manufacturing strategy.

At Macfab, we specialize in leveraging the full potential of 5-axis CNC machining to deliver complex, high-quality components with unmatched efficiency. Whether you’re in aerospace, medical devices, or advanced tech industries, our team is ready to help you accelerate production and exceed expectations.

Contact Macfab today to see how we can streamline your operations and bring your designs to life—faster, better, and more cost-effectively.