Precision Military Components Made with CNC Swiss Lathes

The defence industry has always pushed the limits of what’s possible—and demanded the same from its manufacturing partners. From advanced optics and secure communications to guided munitions and drone systems, modern militaries operate at the leading edge of science and technology. These innovations depend on an array of ultra-precise mechanical and electronic components that must perform reliably in some of the harshest environments on Earth.

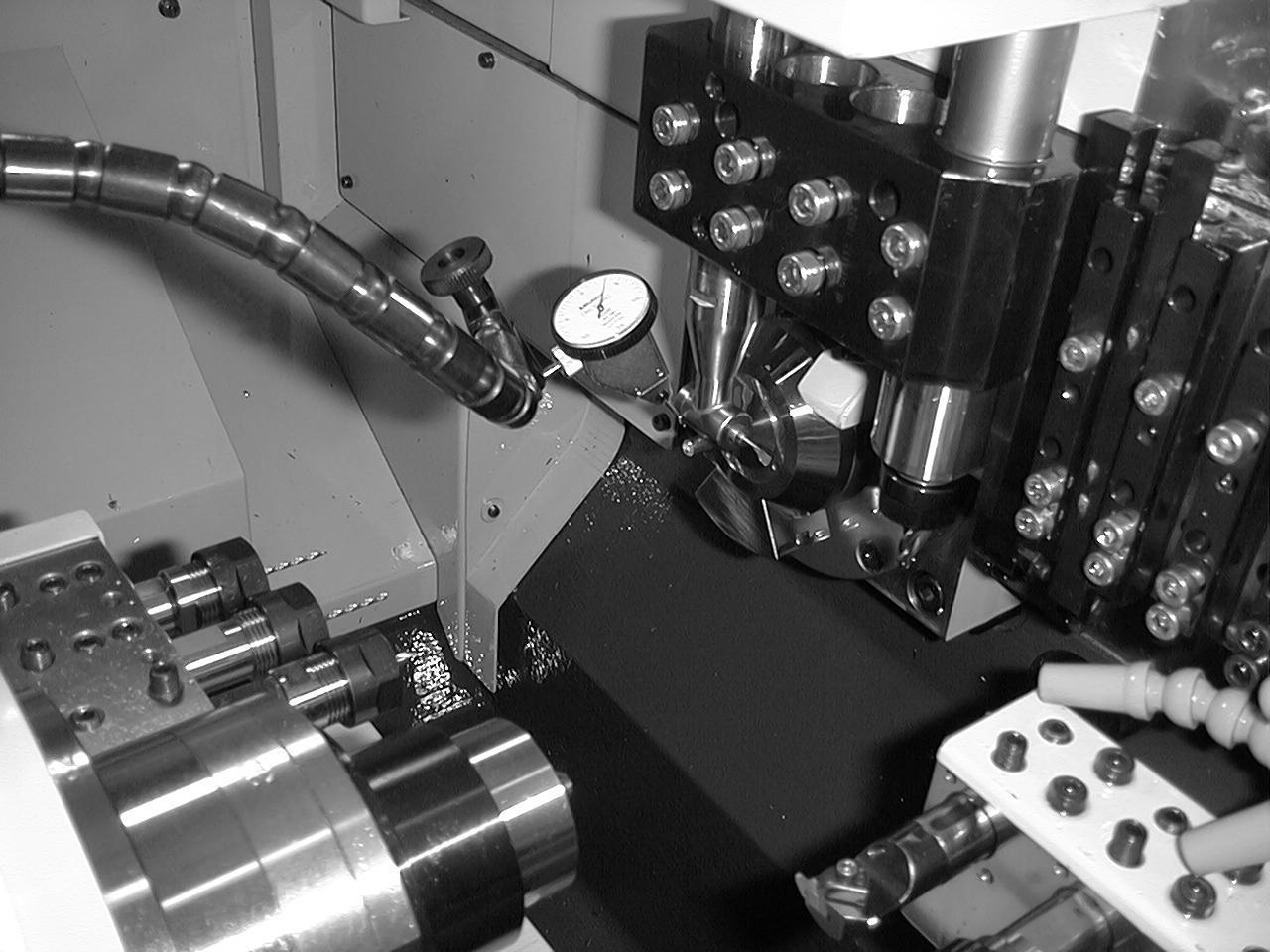

Delivering this level of performance means that every part must meet exact specifications, without compromise. That’s where defence Swiss machining comes into play. Swiss lathes are built for precision and repeatability, making them ideal for the tight tolerances and miniature geometries required in advanced defence systems. When failure is not an option, defence contractors rely on Swiss turning capabilities to keep their systems sharp, compact, and reliable.

What is a CNC Swiss Lathe? Why It’s the Go-To for Complex, High-Precision Parts

To understand why CNC Swiss lathes are trusted for mission-critical parts, it helps to look at how these machines came to define a new standard in precision manufacturing.

A Brief History of Precision

Swiss lathes were initially developed in the 1800s by a Swiss watchmaker to produce intricate screws and micro-components for mechanical watches. While the early versions were hand-cranked and slow, they delivered levels of precision previously unheard of. Today’s CNC Swiss lathes continue to uphold that commitment to accuracy—with the added benefits of automation, speed, and advanced software control.

Over the decades, the evolution of Swiss lathes has mirrored the increasing complexity of the industries they serve. Once used solely for watchmaking, they now play a critical role in aerospace, medical, and defence manufacturing.

Modern machines feature live tooling, multi-axis control, and automatic bar feeders—capabilities that enable manufacturers to produce complex geometries in a single setup with minimal operator intervention. The result is unmatched precision, efficiency, and consistency for even the most demanding applications.

How It Works

What sets the CNC Swiss lathe apart from traditional CNC turning is its sliding headstock and guide bushing. Instead of holding the workpiece in a fixed position, the stock moves through a guide bushing that keeps it supported right where the cutting tool is doing its job. This setup virtually eliminates deflection and vibration, which is critical when machining small-diameter, high-aspect-ratio parts.

This design allows for:

- Precise machining of long, slender components

- Stable holding of very fine raw stock

- Reliable dimensional accuracy in high-mix, low-volume production

The tools are mounted extremely close to the support bushing—sometimes within millimetres—which means the material never extends far enough to wobble or distort under pressure. That’s how Swiss turned components can be made thinner than a toothpick and still meet micron-level tolerances.

Many modern Swiss lathes also feature live tooling and multi-axis capabilities, allowing for the simultaneous execution of cross-drilling, milling, and slotting in a single setup. These elements reduce cycle time, improve repeatability, and minimize the need for secondary operations—an essential advantage when machining complex defence components with tight deadlines.

Top 5 Defence Parts Ideal for CNC Swiss Lathes

With their unmatched ability to machine intricate geometries and hold tight tolerances, CNC Swiss lathes are uniquely suited for producing the high-performance components modern defence systems depend on—especially in compact, rugged environments.

- Optical sensor housings: Built to hold lenses and electronics in perfect alignment under shock and vibration.

- RF (radio frequency) connectors and components: Require tight tolerances to maintain signal integrity across extreme conditions.

- Miniature enclosures for guidance electronics: Compact, sealed, and often made from specialized alloys.

- Missile control fins and flight surfaces: Aerodynamically shaped and built from heat-resistant materials.

- Specialized fasteners and bushings for UAVs: Lightweight, corrosion-resistant, and engineered for repeatable performance.

These parts often require intricate geometries, deep bores, and fine threads that are difficult to machine on conventional lathes. CNC Swiss lathes enable the meeting of these requirements with speed and accuracy, which is ideal for high-mix, low-volume production runs where every part must meet mission-critical standards.

How Swiss Turning Supports Today’s Smart Military Systems

As defence systems become smarter, smaller, and more connected, the need for precise components has only intensified. From soldier-wearable electronics to autonomous drones and missile defence systems, these platforms rely on accurate, miniaturized parts to operate as designed.

Here at Macfab, we’ve expanded our arsenal of Swiss turning machines to meet these growing demands. Whether we’re producing tight-tolerance sensor housings or lightweight mechanical enclosures for UAVs, the challenge remains the same: to produce high-performance parts that withstand unpredictable, often extreme environments.

One of the biggest trends in modern defence is information dominance—knowing the battlefield better than the enemy. That means components must support high-frequency communications, thermal imaging, and laser-guided systems—all of which depend on parts machined with exceptional precision.

For example:

- Self-guiding munitions require sensor mounts and actuator parts that can’t fail in flight.

- Anti-drone systems rely on fast signal processing enabled by finely machined RF casings.

- Optical and thermal scopes must maintain alignment despite shock, vibration, and temperature swings.

Defence CNC turning ensures that these mission-critical parts meet strict performance standards. Without that level of control, the entire system is at risk.

Swiss turning also enables miniaturization for advanced technologies like:

- Jet control surfaces for extreme manoeuvrability

- Components for directed energy and electronic warfare

- Positioning systems that factor in light-speed delays for targeting precision

It’s not just about making small parts—it’s about enabling smart ones.

Macfab’s Swiss Turning Capabilities: What Sets Us Apart

At Macfab, we don’t just own CNC Swiss lathes—we invest in them. We maintain a fleet of state-of-the-art Swiss turning machines capable of producing complex components with consistency and repeatability. Just as significantly, we invest in our people, offering continuous training to ensure every operator understands the fine details of high-precision manufacturing.

Our long-standing relationships in the defence sector have shaped our shop floor and our approach. We are built to handle the technical and procedural complexity that comes with defence work—from tight timelines to rigorous documentation and traceability.

Whether you need a one-off prototype or full-scale production support, our team is equipped to deliver. What sets us apart isn’t just the machines—it’s the full package:

- ISO 9001 & AS9100 certified

- Materials expertise in titanium, aluminum, and exotic defence-grade alloys

- Full in-house quality control, including CMM inspection and reporting

- Compliance with Canada’s Controlled Goods Program (CGP)

We collaborate closely with our customers to understand project requirements, adapt to evolving specifications, and meet rigorous quality standards. When quality, delivery, and accountability matter most, Macfab is the partner you can count on.

Swiss Turning in Action: Meeting the Demands of Miniaturized, Rugged Defence Systems

Building on the unique strengths of CNC Swiss lathes, here’s how Swiss-turned components thrive in harsh, compact, high-performance environments.

Space is always at a premium in modern defence systems. Whether it’s the guidance section of a missile, the inner workings of a radar array, or wearable tech on the battlefield, compact and reliable components are critical.

That’s where Swiss-turned components truly shine. Because they can be machined to extremely small sizes while still maintaining strength and consistency, they’re perfect for:

- Electrical connectors in communication systems

- Compact housings for gyroscopes and accelerometers

- Missile fins and aerodynamic control surfaces

- Enclosures for ruggedized embedded electronics

- Thermal isolation parts for avionics modules

Another key benefit is that Swiss lathes often eliminate the need for secondary operations. By combining multiple machining steps into a single setup, they reduce handling and error, which is perfect for lean, low-to-mid-volume defence manufacturing.

Swiss turning also excels at handling exotic materials common in the defence world, like:

- Titanium for high strength-to-weight ratio

- Inconel and other nickel alloys for heat and corrosion resistance

- Custom aluminum alloys for lightweight, conductive enclosures

These capabilities help reduce part count, streamline assembly, and improve overall system reliability. Swiss turned components also maintain performance through temperature extremes, shock, and vibration. These qualities make them ideal for equipment that operates in the field, under pressure, and without room for error.

Why Partner With Macfab for Your Defence CNC Turning Needs?

From prototype development to full-scale production, Macfab brings experience, precision, and accountability to every defence machining project. We understand that both design engineers and procurement teams are under pressure to deliver innovative solutions—on time and on specification.

For buyers and decision-makers, we offer:

- Proven delivery performance

- Full traceability and documentation

- A responsive, communicative team that solves problems proactively

For engineers, we bring:

- Expert guidance on material selection and manufacturability

- Tolerance control down to the micron

- Precision CNC machining for the most demanding geometries

We also support product lifecycle continuity—from initial design consultation through to production, inspection, and ongoing process optimization. Whether you’re scaling up a new part or refining an existing design, our team is committed to delivering consistent results with the highest level of care and attention.

Let’s explore how Macfab can help bring your next project to life—with precision.