Precision Medical CNC Machining

Machined Components for the Medical Industry

Macfab has decades of experience in precision CNC machining for medical devices, delivering components that meet ISO 13485 and FDA standards. Our clients continue to select us for our deep knowledge of regulatory requirements, thorough record-keeping and traceability of materials, and cleanroom-ready parts delivered directly to our customers’ assembly lines. Our dedication as a total solution medical equipment parts manufacturer includes a full range of services to enable our customers to maintain and grow their market share in the highly demanding precision medical equipment manufacturing industry.

Why Choose Macfab for Medical Device CNC Machining?

With over 50 CNC machines in their Mississauga facility and access to additional expertise and capacity through our parent company Ben Machine, Macfab is well-positioned for high-volume precision CNC work for the medical industry. As a full end-to-end solutions provider, we have made significant investments in non-core services to the medical industry. Our deep expertise, combined with these investments, offers a unique suite of services that enable our customers to realize life-cycle parts cost competitiveness, breakthrough design for manufacturability competitiveness, and sustained market share growth.

– Mass spectrometry

– High-Pressure Liquid Chromatography (HPLC)

– Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

– Quadrapole ICP-MS

– Ion Mobility Photometry (IMS)

– Photoionization detection devices

– Drug delivery systems

– Pump Cavities

– Nebulizers, Lasers

– Surgical devices and tools

– Mass flow meters

– Flow controllers

– Force transducers

– Muscle physiology systems

– Ventilators

– Drug delivery

– Pharmaceutical equipment

– Sensors

Learn how we evaluate advanced engineered medical polymers across a range of production related decision criteria.

Medical Grade Polymers

Considerations When Selecting Medical Plastics (Polymers)

Specialty Services

Macfab has invested significantly in specialty services as a high-precision, full-service medical equipment parts manufacturer.

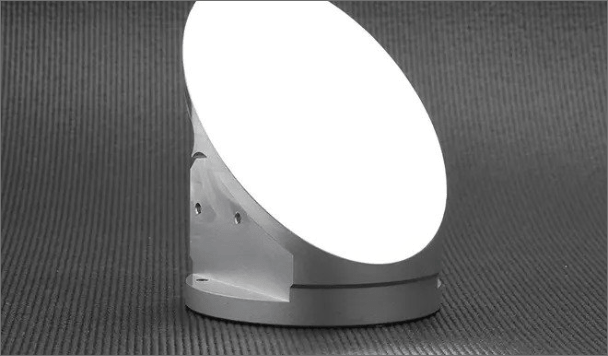

Specialty Finishes

Macfab collaborates with suppliers to provide anodizing and chromate conversion capabilities, saving our customers time and cost. The components arrive at your facility ready for use.

Cleanroom

Macfab’s ISO grade 7 cleanroom allows us to clean your parts, assemble them into a sub-assembly, and then finish testing. We package your parts ready to move smoothly through your facility and into your machinery.

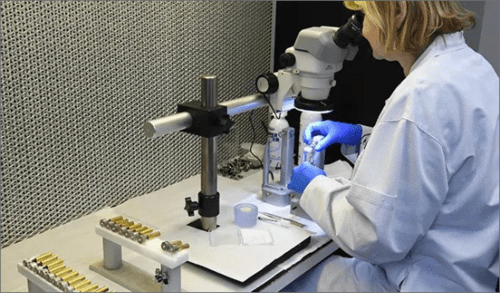

Assembly

Macfab can provide general mechanical assembly of machined components to microscopic assembly of parts. While assembly always appears simple, with the proper fixtures and tooling in-house, Macfab can develop robust processes to reduce scrap and cost.

Quality Testing & Inspection

With the latest CMM and laser inspection equipment, your parts are correct at each process step. Macfab has leak detection and off-gas testing for parts and assemblies to validate their performance before shipping.

Vendor Managed Inventory

Leveraging our advanced ERP system to manage Just-In-Time inventory, vendor-managed inventory, and Kanban agreements, Macfab delivers a 100% on-time delivery rate for customers participating in these programs.